ations. After all, plastic containers

should provide the same level of

safety as that of metal aerosol cans.

The European Commission and

the Aerosol Industry, represented

by their associations – first and

foremost the FEA (European Aer-

osol Federation) – have strongly

emphasised this aspect. This

leads to the question as to what

conditions metal cans really with-

stand, as a kind of established

safety criterion. We already know

that cans should withstand 50°C

and the related pressure in the

aerosol pack.

Characteristics

of metal cans

Metal cans can resist tempera-

tures higher than 50°C. Melting

points are far above those known

for plastics. The limiting factor is

in fact the filling, especially the

propellant, which causes the in-

crease in pressure at elevated

temperatures. In fact, sometimes

even higher temperatures than

50°C are recorded. Inside a store’s

glass show window, the tempera-

ture can go above 60°C.

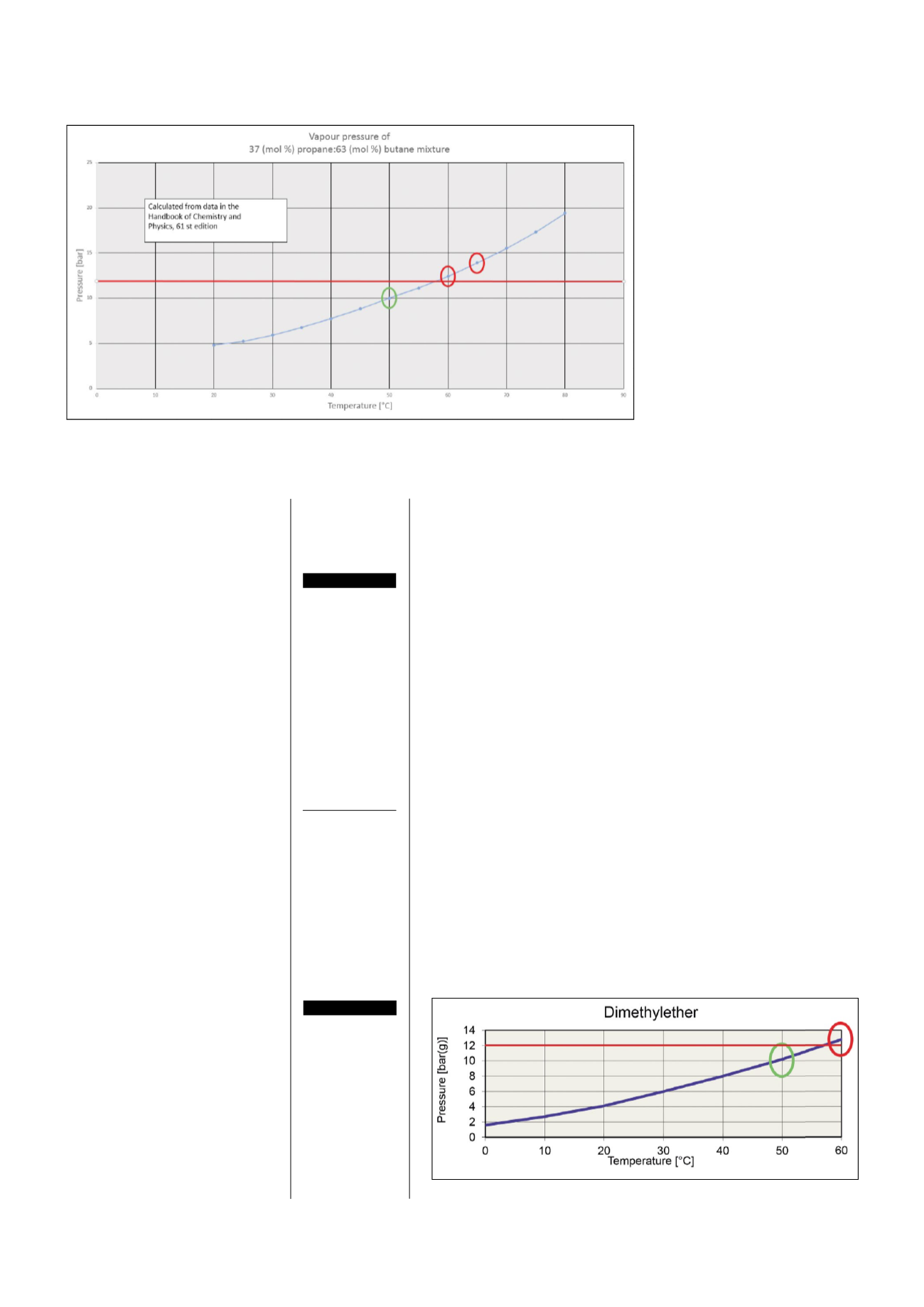

Fig. 1 shows pressure as a func-

tion of temperature in the case of

a mousse containing a standard

filling with a propane/butane

blend. At 50°C the pressure is less

than 12 bar, which is the permit-

ted pressure according to the

standards of the

European Aero-

sol Dispensers Directive

(ADD).

An appropriate metal container

would be constructed to resist 12

bar without deformation, and

even up to 18 bar. Such an aerosol

should easily resist temperatures

above 60°C. In actuality, such

aerosols can cope with tempera-

tures up to 70°C.

In a test, it can be shown that

cans like this burst at a tempera-

ture above 70°C. In a temperature

profile of a stability test* the cans

described above had been ex-

posed to high temperatures. 50

cans had been heated to 70°C and

the temperature was sustained for

five hours. Then the temperature

was raised to 75°C and kept for

another five hours.

Observed defects*

Two cans showed high bottom

deformation. All cans showed

small deformation in the bottom

area and slight deformation in the

shoulder/valve area as the valve

started to lift up. Four cans

showed high deformation in the

Fig. 1: Temperature related pressure of a propane/butane-blend

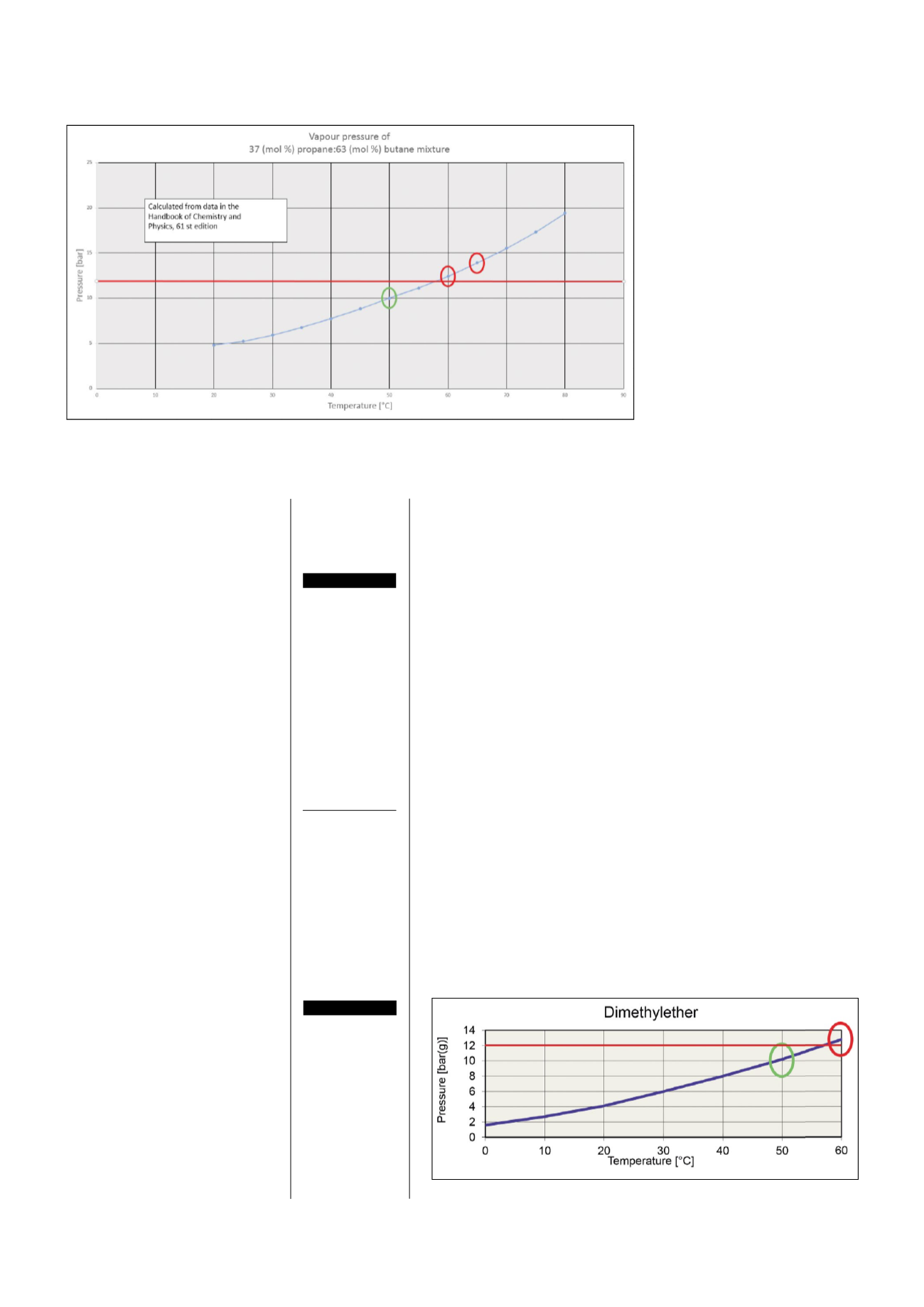

Fig. 2: Temperature-related pressure of dimethyl ether

1975). This was the first report

about microorganisms capable of

consuming man-made materials.

There is also a microorganism

that lives in an insect, which can

digest types of plastics such as

PE. There are bacteria that can be

found in moths (reported 2014)

which convert polyethylene into

nourishment for the moth. Al-

though the effect is very small,

there is evidence that nature in-

vents bugs that could possibly

consume any type of plastic.

However, the reported consump-

tion rates are quite low: it would

take about 300 years for a PET

container to be consumed. The

fact that plastics can be absorbed

more quickly back into the earth

than assumed up until now might

be an argument to consider plas-

tics as a material to produce aero-

sol containers.

On the other hand, we need to be

aware that in the future, plastics

can possibly be subject to micro-

biological contamination, which

leads to the question of whether

biocides are required to protect

the plastic material.

Restrictions for

plastic containers

The conclusion is that for plastic

containers, there are some restric-

tions related to their stability

which again leads to cost consider-

LIMITATIONS

Some limitations

for plastic cans

are even

more

restrictive

than

those for metal

cans

Shaping plastic

cans can be costly

PLASTIC CANS

Transparent

plastic cans

have

enhanced

appearance

and decoration

options

PACKAGING

52

l

COSSMA 4 I 2017